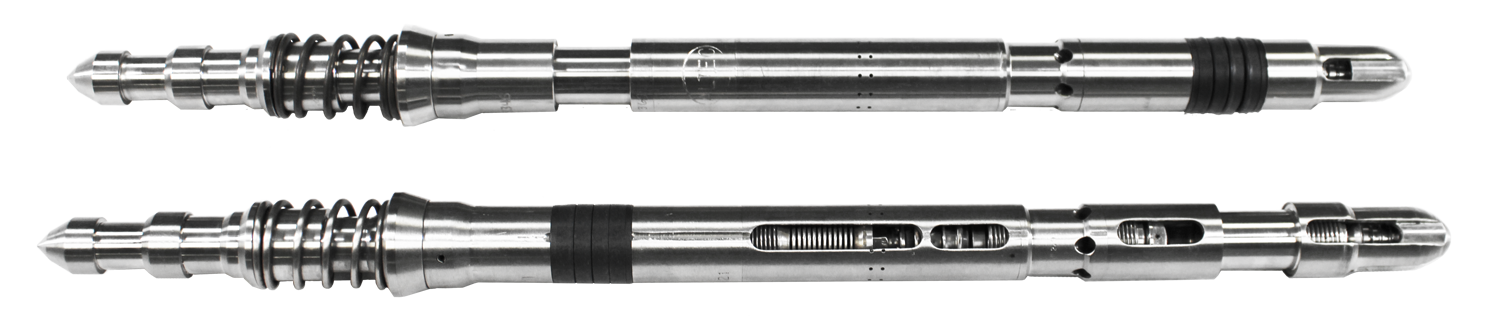

ABBA™ Pilot Valve

For Intermittent Tubing Flow

The ABBA™ Pilot Valve is a 1” wireline-retrievable, pilot-operated gas lift valve that is primarily controlled by injection gas pressure. The valve is typically installed in a 1” side-pocket gas lift mandrel and used to control injection gas pressure and its flow from the casing annulus into the tubing during intermittent gas lift operations.

Intermittent gas lift requires large volumes of gas to be injected rapidly into the tubing, for short periods of time, in order to displace a slug of fluid from the point of injection, to surface. The control of gas during cyclic operation is enhanced by the valve’s ability to control operating spread (difference in valve opening and closing pressure) while maintaining a large primary injection port for instantaneous gas injection.

OPERATION

The power section of the valve is either fully open, or fully closed, as determined by the pilot section. Injection gas enters the pilot section of the valve and acts on the effective area of the bellows. As injection pressure overcomes the pre-charged nitrogen pressure in the bellows, the bellows is compressed and lifts the ball-stem off the seat.

Injection gas then flows down past the seat and overcomes the preset spring force of the power section. As the power section opens, a high volume of injection gas flows through the valve, past the reverse-flow check valve into the production tubing. Port sizes available for the pilot section are 1/8” to 3/8” in 1/16” increments.

FEATURES/BENEFITS

• Small operating spread between the valve opening and closing casing pressures

• Large flow area for high-volume gas injection

• Stainless steel or premium materials available

• Three-ply, nickel-copper alloy bellows

• Mechanical stop prevents bellows over stroke

• Bellows dampening fluid to prevent fatigue and stem-seat pounding

• Replaceable floating seat (Tungsten Carbide available)

• Integral reverse flow check valve with resilient and metal-to-metal seals

• Pressure rating up to 1400 psi (124 bars) test rack opening pressure

• Temperature rating of 250° F (176°C) (Standard Service)